Saturday, November 20, 2010

Supplier Selection OR Management

Wednesday, October 6, 2010

Supply Chain

Supply Chain includes Inbound and Outbound Logistics and also the Manufacturing Unit.

From the following Fig/Diagram it will focus more on the concept stated above.

Inbound Logistics:-

Inbound Logistic concept comes into picture from the purchase of raw material till it reaches mfg. Unit.

Dept. which involves in this type of Logistics are…

Purchasing Dept.

Internal Logistics Dept.

Warehouse

Mfg. Unit

Purchasing Department:

It purchases raw material acc. To the order taken by the marketing dept. Mkt. dept. takes order acc. To the customer requirement and suggests about particulars to this dept.

Purchasing dept. acc. to the needs and quality of the material purchases the same.

Internal Logistics Dept.:

It moves the purchased raw material from the point of purchase to the point of store where raw material is stored before mfg. of goods or products.

Mfg. Unit:

Mfg. Unit contains fully automated machines controlled by computer controlled machines like FMS the raw material when moved towards mfg. unit it is deloaded and the robots at the machines keeps the raw material on chain and one by one raw is processed into finished product. When goods are processed into finished product the robots at another end helps to keep it in a vehicle to send it in finished goods warehouse.

Outbound Logistics:

Outbound Logistics dept. delivers the finished goods or product to the customer as per their requirement.

It is the responsibility of the dept. to determine the shortest route and through which transportation cost should be minimum.

Tuesday, April 20, 2010

Decision Phases in Supply Chain

Successful SCM requires decisions relating to the flow of Information, Product and Fund.

There are three such Decision phases which are explained below----

Supply Chain Strategy -

This type of decision is taken by the management mostly. As the decision includes long term prediction and contains cost of say very expensive if it goes wrong. The market conditions should be taken into consideration at this stage.

The prediction and condition of market for next years are important in these decisions. The decision may include the structure of supply chain after making structure the tasks and responsibilities of each stage like as we know there is transportation storage of material produced. Production of material, plant location which should be easy for transporters to load material and to dispatch at their said location. Location of warehouses for storage of finished product or good and so on. All these decisions are strategic decision s taken by higher authority.(Management).

Supply Chain Planning -

By keeping in mind the supply chain design phase the next i.e. Planning should be done according to the demand and supply view. The most important to know about demand and supply is Market Research and the Component of Mkt. Research.

The another thing which i would like to put in front of you is the competitors and strategies they are following to meet their customer requirement. Demand may be different in different market. By forecasting it which market will be provided the finished goods from which plant is planned in this stage. Everyone in this field or firms try to make the overall process as flexible as they can make it. The supply chain design phase if performs good in shorter term the planning is said to be successful.

Supply Chain Operations -

Operations decisions are those that should be made within minutes, hours or days. The aim of this phase is reducing uncertainty and performance optimization.

All that is involved in this phase is from customer order handling to providing the customer with that product.

Suppose a customer requires a product which your company manufactures, It is first of all the responsibility of marketing department to take order, convey it to production dept. and inventory dept., production dept. produces acc.to the customer need sends it to warehouse through a proper channel and distributor to customer within a time frame. All the department in this process involved should try to improve the performance and minimize uncertainty.

Saturday, March 20, 2010

Customer Complaint Handling

Customer of any company or industry or other might have many kinds of problem regarding product or services which they are getting from their supplier.

These kind of problems are handled/solved by a special group of people in that particular company,be cause of which their custormers should be satisfied.

The Process starts with lodging the complaint/registration of complaint or any dissatisfaction regarding the product or servi ce and company tries to resolve it and make sure that the customer is satisfied with their services.

Customer Complaint are of Categories like…….

Customer Complaint Category

Image By:- http://pradipsuryavanshi.blogspot.com

Image By:- http://pradipsuryavanshi.blogspot.comProcess through which most of the companies go through for customer complaint handling is as below…….

Customer Complaint Handling Process

Wednesday, January 20, 2010

e-bidding (Logistic Department)

e-bidding

e-bidding as the name suggests is nothing but electronic medium. It means the process of bidding and auction. It is done through the modern techniques what we call it as Online.

The process of e-bidding can be summarized as follows-

Each and every dept. in a particular industry has diff. e-bidding process. Out of these we will see e-bidding process in Logistic Dept.

Zone Wise- Zone wise quotations for transportation of various finished products to respective zones and its destinations are invited.

The diff. Industry has diff. destinations in South, North, East, West zones according to that they appoint agent and through that they deliver their product.

The classification of the quotation is done on the basis of lowest rate given by various transporters for particular destination in a zone.

Avg. Cost is calculated on the basis of quantity of material which is transported previously for a particular destination.

Various transporter are registered as bidder to participate in online Reverse Auction.

Bidders are provided with the user name and password to participate in online Auction process fixed on a day decided with flexibility.

When auction starts bidders are asked for bidding below offset value.

Time is fixed for the process say One Hrs. Or Two Hrs.

There is a decremental value which is decided by that company only.

Within the time frame whatever be the value which is lower than offset value is finalized.

If the bid is entered by the bidder in last 3 or 4 min. then the auction process is also postponed by the 3 to 4 min.

And after that the contract is given to the bidder selected for a period specified in

Agreement.

As per the terms and condition the bidder agreement is signed by both parties.

Tuesday, January 5, 2010

CHANGE MANAGEMENT ( O. M.)

OBJECTIVES:

· To Understand the concept of the change management.

· To understand the points which focus is maximized during which change management.

· To give brief idea about the challenges and the critical skills involved in change management.

· To get acquainted of the knowledge about the new technologies.

· To develop the concept of coordination.

Introduction

Today the world is changing very fast with the improvement in technologies the new technology helps to come in contact with eachother and share the things which they have. Also helps to get knowledge about the technology which they don’t have. Also the websites and the other instrument helps us to do the things properly, tactfully and timely.

If we focus on technologies in operation management there are lot of techniques used to reduce the time and cost and increase or develop a quality product or service.

All this is because of the change that taking place in various fields.

There is a cut-throat competition among the service provider. To sustain or survive in a market it is necessary to adopt a change.

The change might be in any field like political, social, environmental, technical, and so on. It is difficult to adjust with the new environment as the processes are habitual. So there is a need to give a special attention towards the change and manage it skillfully.

The change as stated above can be explained diagrammatically as below.

POLITICAL CHANGE : You will think that how political change is related to the change management. The Organisation involved in BPR may have contacts with the politicians. The policies framed by one politician may be diff. from new one. Also the govt., intervenes for many reasons regarding the duties(Tax and Customs) and all that.

POLITICAL CHANGE : You will think that how political change is related to the change management. The Organisation involved in BPR may have contacts with the politicians. The policies framed by one politician may be diff. from new one. Also the govt., intervenes for many reasons regarding the duties(Tax and Customs) and all that.ENVIRONMENTAL CHANGE : As we know that the this change includes macro and micro elements that affect the processes in organization. The internal and external factors both affects output. The internal factors are the hierarchy in management and the resources available and the external factors like competitors the internal factors contributes of Man, Material, Money, Machine.

TECHNOLOGICAL CHANGE : This type of change is needed by every one who wants to survive in the market. The changes in technology is helping BPR organization to minimize the cost and time and maximize the profitability. There are techniques in organization like PERT, CPM, CAD, CAM and so on. To manage the change the employees in an organization should make aware of the things that are new.

Three perspectives are important while managing change.

By delegating the authority to the subordinate he might make the others responsible for the tasks in the organization (Training program). Monitoring and controlling the change is the important as the initiative of the change management.

ROLE OF MEMBERS IN THE ORGANISATION:

The workers in the organization or the members are very much afraid of change in the process or of new policy and so on.

The members feel that they will be kicked of if they do not perform well. Also there is a fear of job loss due to the change. So that workers are not willing to adopt the change in any ongoing process and Reengineering (BPR).

The members if transferred from one dept. to other they are not willing to go, because of the affection they have with their near one in the organization. They get fear of how can I work without him/her in other dept.

So that without any fear the members should accept change and what programmes the management is organizing should be attended.

According to the skills and tech. they have they should take initiative to handle the certain task.

There is politics in any organization the management should be responsible for that to manage it properly.

The employees in the organization feel fear of job loss due to reengineering because of the new automated machines labour work gets minimized and because of reengineering the job cuts and relocation of division and dept. takes place.

BPR Process focus on the quality output. So the workers with clumsy or gauche attitude are removed there and there only.

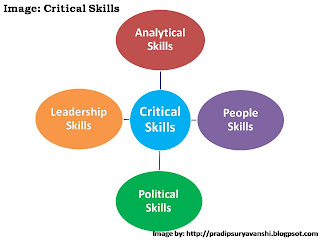

Also there are skills which are needed in managing change those are “PALP”.

· Political skills

· Analytical skills

· Leadership skills

· People skills

Change management concept is required to get about the framework of Boddy & Buchanan Framework which is depended upon three models.

Change management concept is required to get about the framework of Boddy & Buchanan Framework which is depended upon three models.· Project Management

· Participative Management

· Political Perspective

(NOTE :Needy people or student are suggested to collect more information about the topic discussed above with frameworks.)

Wednesday, December 9, 2009

Push/Pull view of Supply Chain Process

Push/Pull view of supply chain is very useful when considering strategic decisions relating to supply chain design.

Push/Pull view of supply chain is very useful when considering strategic decisions relating to supply chain design. Pull Process depends on the customer demand whereas Push processes are the predictions, i.e. manufacturer produces gooods and services thinking that there will be demand or requirement for the product or service produced.

Pull Process depends on the customer demand whereas Push processes are the predictions, i.e. manufacturer produces gooods and services thinking that there will be demand or requirement for the product or service produced.